Industrial Switchgear Testing — Verified for Safety, Performance & Compliance

Industrial Power Gear — Fully Tested. Field-Ready

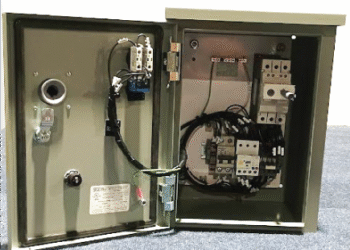

At Pinnacle Power & Controls, we provide end-to-end switchgear testing and commissioning services that ensure your equipment performs safely, efficiently, and in full compliance with NEC, UL, and ANSI standards. From in-shop Factory Acceptance Testing (FAT) to on-site startup verification, we validate every connection, component, and control to help you minimize risk and avoid delays during energization.

Whether you’re deploying low-voltage UL 891 gear or 15kV ANSI C37 systems, our QA and engineering teams perform thorough validation for insulation resistance, breaker functionality, arc flash protection, labeling, and metering accuracy.

We help industrial clients across the U.S. commission mission-critical gear quickly, without cutting corners. If it leaves our shop, it’s field-ready, AHJ-approved, and backed by engineer-grade testing.

Comprehensive Switchgear Testing Services We Provide

At Pinnacle, every switchgear system is subjected to a rigorous QA and commissioning process that includes in-shop validation, documentation, and — when required — on-site testing and startup support. We follow industry-accepted protocols and provide complete test reports for your records and AHJ submittals. Our approach ensures safe energization, proper fault protection, and compliance with UL, ANSI, and NEC specifications.

From thermal scans and insulation resistance to SCADA verification and arc flash mitigation, our testing protocols are engineered to reduce risk and build confidence.

Testing Services We Offer:

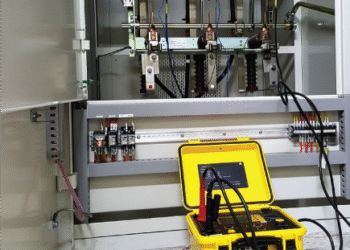

Factory Acceptance Testing (FAT)

Pre-shipment testing of every panel — including point-to-point wiring checks, relay verification, labeling, torqueing, and documentation

Insulation Resistance & Dielectric Testing

Verification of conductor insulation and dielectric strength to prevent breakdowns under load.

Breaker Functionality & Protection Coordination

Testing trip units, timing, and selective coordination to ensure proper fault handling and safety clearances.

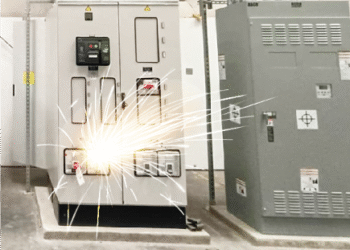

Arc Flash Mitigation Testing

Verifying arc flash barriers, relays, and system configurations — helping you reduce incident energy and meet NFPA 70E.

SCADA & Metering Validation

Ensure all relays, PLCs, HMIs, and meters are properly configured and communicating as specified.

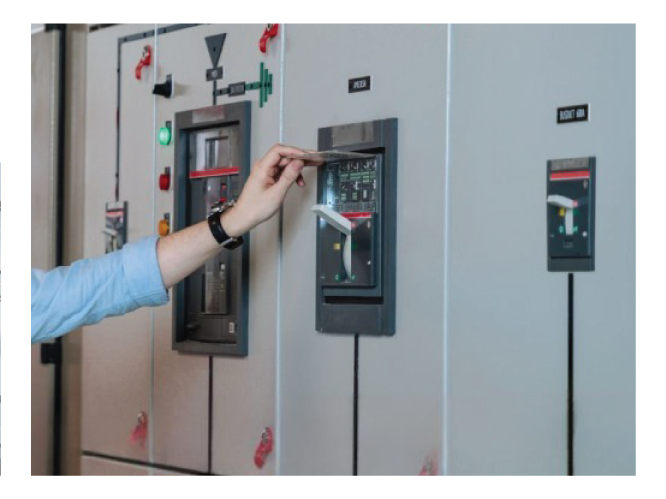

On-Site Start-Up & Field Commissioning

We assist your team in final power-up, grounding checks, and energization, including breaker close/open sequencing and safety validation.

Trusted Testing & Commissioning for Critical Power Environments

Pinnacle Power & Controls supports testing and commissioning services across industrial, utility, and infrastructure sectors — wherever reliable, safe power distribution is mission-critical. From factory-built low-voltage systems to complex 15kV medium-voltage installations, we help ensure that every panel operates as designed, integrates seamlessly, and complies with applicable codes.

Whether you’re energizing a new facility or retrofitting legacy gear, our QA and field testing services reduce downtime, accelerate approvals, and safeguard personnel.

Industries We Serve:

Why Industrial Teams Trust Pinnacle for Switchgear Testing & Commissioning

At Pinnacle Power & Controls, we do more than build UL-listed switchgear. We ensure it performs in the field. From factory acceptance testing (FAT) to on-site commissioning support, our team provides rigorous quality assurance and compliance services tailored to your voltage class, application, and regulatory environment.

Whether it’s a 480V panel with protective relays or a 15kV system with arc flash mitigation, we test for reliability, safety, and code adherence before your gear ever sees power. With in-house QA protocols and field-ready documentation, we help EPCs, plant engineers, and utility partners meet commissioning schedules and avoid costly rework.

What Sets Us Apart:

Engineer-Verified Answers About Switchgear Testing & Commissioning

Every panel undergoes full QA and Factory Acceptance Testing (FAT) — including insulation resistance, continuity, breaker operation, relay logic, SCADA I/O simulation, and arc flash mitigation checks (if specified). We provide detailed test reports and QA documentation with each shipment.

Yes. We offer on-site commissioning services, including final torque verification, power-up support, trip testing, and relay calibration. This helps ensure systems are safely energized and meet AHJ and utility interconnection requirements

Absolutely. We support protection scheme validation, relay programming, and time-current curve coordination to reduce arc flash exposure and meet NFPA 70E requirements.

We ship each system with a complete documentation package: one-line diagram, nameplate data, UL/ANSI/NEMA labels, torque specs, relay settings, test results, and AHJ-ready QA checklist.

For most low-voltage systems, lead times range from 2–4 weeks. Medium-voltage or E-House systems typically run 6–10 weeks, including QA, FAT, and integration. Rush timelines available.

Let’s Ensure Your Switchgear Is Compliant, Safe, and Field-Ready

At Pinnacle Power & Controls, we don’t just build UL-listed switchgear. We make sure it’s tested, documented, and ready to energize. Whether you’re commissioning a 480V power distribution board or a 15kV utility interconnect, our QA-tested panels and on-site support ensure you pass inspection and power up safely.

From arc flash mitigation to FAT reports, trip coordination, and relay calibration, our team handles every detail, so your switchgear isn’t just built right, it performs right.