Power Solutions

Industrial Power Solutions – Custom Switchgear & MCC Systems Engineered for Reliability and Scale

At Pinnacle Power & Controls, we design and build UL‑listed and ANSI C37‑certified power solutions for industries that demand the highest levels of performance and uptime. Our portfolio includes custom low‑ and medium‑voltage switchgear, prefabricated E‑House systems, modernization and integration services, and turnkey installation capabilities, all engineered and built in the USA.

Whether you’re powering a 480 V manufacturing line, a 15 kV utility interconnect, or a remote data centre, we deliver fit‑to‑spec solutions that are engineer‑to‑engineer designed and rapidly delivered. From a new distribution line‑up to a factory‑integrated E‑House or a complete retrofit of your legacy gear, our team provides the expertise and support you need to keep your operations safe, scalable, and compliant.

Why Reliable Power Distribution Matters

In industrial facilities, power distribution is the foundation that keeps processes running safely and efficiently. Well‑designed switchgear allows electrical energy to be controlled, protected, and isolated without shutting down production or compromising worker safety. From manufacturing lines and data centers to water treatment and renewable energy operations, reliable switchgear must deliver four essential qualities:

- Continuous uptime – Redundant feeders, main‑tie‑main configurations, and selective coordination keep your facility online even when faults occur.

- Safety – Compartmentalized sections, arc‑flash mitigation, and fault isolation protect personnel and equipment during normal operation and maintenance.

- Scalability & growth – Modular sections, draw‑out breakers, and prefabricated E‑House options make it easy to expand or reconfigure as your needs change.

- Compliance & assurance – Adhering to UL 891, ANSI C37, NEC, and NFPA 70E standards ensures your system remains code‑compliant and insurable.

By prioritizing reliability and safety in your power distribution design, you protect your investment, support future growth, and ensure uninterrupted operation of your critical infrastructure.

Our Power Solutions Line‑Up

Below you’ll find a summary of the power distribution systems and services we offer. Each category links to a detailed service page where you can learn more about technical specifications, options, and typical applications.

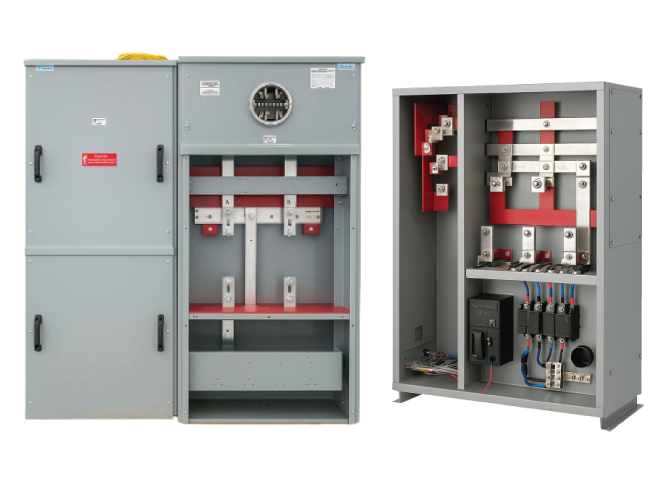

Low‑Voltage Switchgear (UL 891)

Pinnacle’s UL 891‑listed low‑voltage switchgear is custom‑engineered for distribution, control, and protection up to 600 V. Whether you need a main‑breaker, main‑tie‑main, transformer, or multi‑source configuration, our assemblies provide robust protection and easy maintenance.

- Voltage & ratings – 240/120 V single‑phase or 480/277 V three‑phase; standard 400 A–5 000 A ratings with higher capacities available on request.

- Enclosures – Indoor and outdoor NEMA 1, 3R, or 12 options for dust, moisture, and weather protection.

- Bus systems – Choice of copper or aluminum bus bars, braced to handle short‑circuit currents with optional insulated bus for enhanced safety.

- Arc‑flash mitigation – Segmented compartments, relays, and barriers help reduce incident energy and support NFPA 70E compliance.

- Smart communications – Integrated metering, PLC/SCADA connectivity, and remote monitoring enable diagnostics, automation, and smart‑grid integration.

👉 Explore our Low‑Voltage Switchgear for detailed specifications and options.

Turnkey Switchgear Installation

For projects that require a single point of contact from design to commissioning, our turnkey installation services manage the entire electrical scope. We handle device selection, fabrication, delivery, installation, and testing to provide a fully functional and compliant system.

👉 Explore our Turnkey Installation Solutions for start‑to‑finish project support.

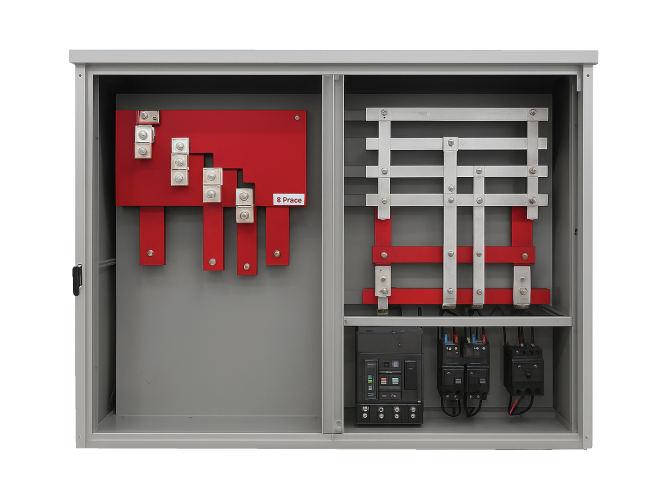

Prefabricated Switchgear Buildings (E‑Houses)

To accelerate deployment and minimise on‑site work, we manufacture factory‑integrated switchgear buildings — also known as E‑Houses — that house your electrical gear, control panels, HVAC and protection systems. Built to your one‑line diagram and voltage class, each unit arrives fully wired, tested and ready to energise.

Types of E‑Houses include:

- Modular multi‑room buildings – Multi‑section enclosures for large switchgear line‑ups and integrated control gear, designed for segmentation, safety zoning and scalability.

- Walk‑in switchgear enclosures – Climate‑controlled buildings for permanent facilities such as substations, water plants and manufacturing control rooms.

- Containerised E‑Houses – Reinforced ISO containers outfitted as switchgear rooms for transport, temporary projects and harsh environments.

- Skid‑mounted switchgear rooms – Portable, pre‑wired structures mounted on skids for rapid deployment in oilfields, modular sites or emergency power projects.

Every E‑House includes lighting, metering, relays, SCADA integration, HVAC and fire suppression, and is FAT‑tested for immediate drop‑in installation.

👉 Discover our Prefabricated Switchgear Buildings for more options and details.

Switchgear Modernization & Integration

Modernizing legacy switchgear keeps your facility safe, reliable and compliant. Our UL‑listed modernization services update obsolete components and integrate modern protection and control technologies while retaining your existing footprint.

- Breaker retrofits & upgrades – Replace oil or obsolete breakers with modern vacuum or air‑insulated types, available in draw‑out or fixed‑mount designs.

- Busbar & conductor improvements – Upgrade to higher‑rated copper bus and improved bracing for better fault‑current handling.

- Relay & protection modernization – Install digital relays with arc‑flash mitigation, fault detection and SCADA‑ready communications.

- SCADA & metering integration – Integrate meters, PLCs and network communications for real‑time monitoring and remote control.

- Control panel integration – Coordinate your switchgear with generator ATS, PLC panels and MCCs for unified operation.

Unsure whether to retrofit or replace? Our Retrofit vs Replace guide helps you compare budgets, downtimes and code requirements to find the right solution.

👉 Review our Modernization & Integration Services to explore upgrade options.

Switchgear Testing & Commissioning

Ensuring that your gear operates exactly as designed requires rigorous testing before shipment and comprehensive commissioning in the field. Our QA program covers the entire lifecycle from FAT through on‑site startup.

- Factory acceptance testing (FAT) – Pre‑shipment tests cover wiring checks, relay verification, labeling, torqueing, and documentation.

- Insulation & dielectric testing – Verify conductor insulation and dielectric strength for code compliance and reliability.

- Breaker functionality & protection coordination – Validate trip units, timing, and selective coordination to handle faults properly.

- Arc‑flash mitigation testing – Confirm that barriers, relays,s and system configurations reduce incident energy exposure.

- SCADA & metering validation – Ensure that relays, PLCs, HMI,s and meters are configured and communicating correctly.

- On‑site startup & commissioning – Support your team with grounding checks, energization, interlock verification, and operator training.

👉 Schedule Testing & Commissioning Services to ensure your system performs as intended.

Technical Specifications & Capabilities

Our power solutions are built to meet a wide range of voltage, current, and environmental requirements. Here’s an at‑a‑glance overview:

|

Specification |

Description |

|

Ampere range |

400 A–5 000 A standard; higher capacities available on request |

|

Voltage classes |

240/120 V or 480/277 V for low‑voltage; 5–15 kV for medium‑voltage |

|

Bus materials |

Copper or aluminium bus bars, insulated and braced for fault currents |

|

Enclosure ratings |

NEMA 1, 3R, 4X or 12; indoor and outdoor options |

|

Generator & ATS ready |

Seamless integration with standby generators and automatic transfers |

|

Compliance |

UL 891, ANSI C37 and EUSERC listed; NEC and NFPA 70E compliant |

|

Lead time |

Standard 6–10‑week delivery; rush options available |

Beyond these baselines, we customise every system to your application. Options include insulated bus bars for increased safety, seismic‑rated enclosures, corrosion‑resistant finishes and integrated surge protection. If you have unique requirements—such as higher amperage, different voltage classes or specialized enclosure ratings—our engineers will design a solution that meets them.

Our Process: From Concept to Commissioning

We handle every aspect of your project, from initial concept through operational turnover. Working with Pinnacle means you get a single point of responsibility and engineer‑to‑engineer support at every stage.

Consult & Design

We start by reviewing your one‑line diagram, process requirements, and site constraints. Our engineers perform load, short‑circuit, and coordination studies to design a system that meets your performance, safety, and regulatory goals.

Engineer & Build

All switchgear, E‑Houses, and control panels are fabricated in our UL‑listed facility. We control quality, schedules, and documentation, and we offer factory acceptance testing (FAT) so you can witness your system before it ships.

Deliver & Install

We manage logistics and rigging to deliver your gear safely. Our field teams perform installation, wiring, grounding, and labeling to ensure your system is set up correctly.

Commission & Train

On-site, we verify protective settings, perform functional tests, and energize the system. We also train your operators and maintenance personnel on safe operation and upkeep.

Support & Maintain

Beyond commissioning, we provide ongoing modernization, retrofits, maintenance, and remote monitoring. Our engineer‑to‑engineer service means you always have a knowledgeable partner to keep your system running at peak performance.

Industries We Serve

Our power solutions are trusted across the energy, industrial, and technology sectors. We customize each system to the environment, load profiles, and regulatory standards of the industries we serve

Why Choose Pinnacle

When you choose Pinnacle Power & Controls, you’re partnering with more than a fabricator—you’re working with an engineering resource committed to performance, safety, and compliance.

- Engineer‑to‑Engineer Collaboration – Work directly with our electrical and control engineers from initial concept to final commissioning.

- Made in the USA & Fast Delivery – All gear is built in Missouri and shipped nationwide. Standard lead times range from a few weeks to a few months, with rush options available.

- Certified & Compliant – Our assemblies are UL 891‑ and ANSI C37‑listed and built to NEC, NFPA 70E, and local utility requirements.

- Turnkey & Integrated Solutions – Design, fabrication, prefabricated buildings, modernization, testing, and installation are all under one roof, simplifying procurement and coordination.

- FAT‑tested & AHJ‑ready – Every system is FAT‑tested and shipped with complete documentation for AHJ approval.

- Customization & Scalability – We match or reverse‑engineer your existing layout and provide scalable solutions for future expansion.

FAQs

Yes. Our low‑voltage gear is UL 891‑listed, and our medium‑voltage gear complies with ANSI C37 standards. Prefabricated buildings use UL‑listed gear and are built to NEC and ANSI requirements.

We build low‑voltage systems up to 600 V and medium‑voltage systems up to 15 kV. Systems are designed to your one‑line and load requirements.

Absolutely. We can integrate owner‑furnished breakers, relays, UPS systems, SCADA panels and PLC racks. Let us know your BOM or drawings, and we’ll coordinate accordingly.

Lead times vary by complexity. Retrofit‑ready gear can ship in as little as 2–4 weeks, while full replacement systems and prefabricated E‑Houses typically take 6–10 weeks. Rush builds are available.

Yes. We specialize in reverse engineering legacy panels and matching form, fit, and function so your replacement gear drops into your existing space.

Let’s Power Your Next Project with Confidence

At Pinnacle Power & Controls, we don’t just manufacture switchgear—we deliver engineered power solutions tailored to your facility’s demands. Whether you’re upgrading a legacy distribution panel, specifying a new 480 V lineup, or interconnecting to a 15 kV utility grid, our team provides safe, reliable, and compliant systems built to your specifications.

Ready to get started?