Project Support & Engineering

Project Support & Engineering Services – Full‑Lifecycle Electrical Support Built in the USA

At Pinnacle Power & Controls, we don’t just build gear — we stand by our customers through every stage of their power and control projects. From concept and design to installation, commissioning and modernization, our engineer‑to‑engineer team provides full‑lifecycle support that keeps your facilities safe, compliant and operational. All services are performed in our U.S. panel shops and delivered worldwide.

Why Project Support & Engineering Services Matter

Power distribution and control systems are complex and heavily regulated. Without expert guidance, projects can suffer from undersized equipment, mis‑coordinated protection, delayed commissioning and unsafe installations. Our full‑lifecycle support tackles these issues head‑on by focusing on four key pillars:

Efficiency & uptime: We start with detailed one‑line diagrams, load flow and short‑circuit studies to make sure your system is properly sized and coordinated. The result is a power distribution network that runs smoothly and avoids nuisance trips.

Safety & compliance: UL‑listed assemblies, NEMA‑rated enclosures, SCCR labeling and well‑coordinated protection schemes help meet NEC, ANSI and NFPA codes while protecting personnel and equipment.

Flexibility & growth: Modular designs, prefabricated MCC buildings and well‑documented wiring make it easy to expand or reconfigure your facility without starting from scratch.

Cost & risk reduction: By working with a single partner from design through installation and modernization, you avoid costly change orders, reduce coordination issues and keep your project on schedule.

Our Project Support & Engineering Services

Consult & Design

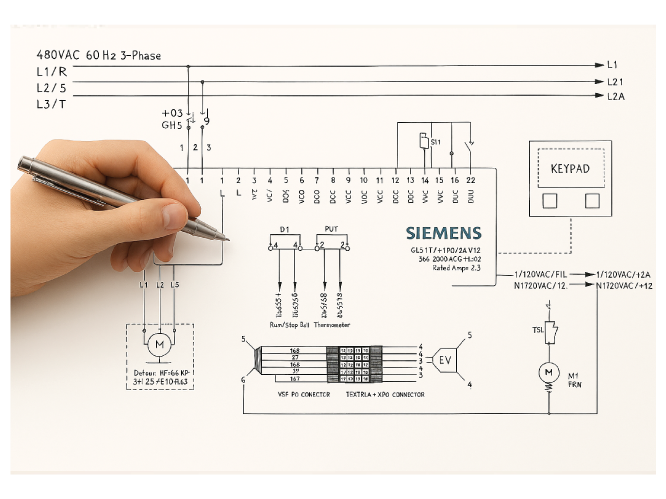

Our engineers partner with you at the earliest stages to lay a proper foundation. We develop detailed one‑line diagrams and perform load flow, short‑circuit, coordination and arc‑flash studies to ensure your system is properly sized and protected. Based on your load profiles and fault currents, we select breakers, starters, drives, relays and protective devices, and determine appropriate NEMA 1/3R/4X/12 or Class I Div 2 enclosures. We also calculate available fault currents, establish short‑circuit current ratings and produce SCCR and arc‑flash labels and stamped drawings. At the end of this stage you receive stamped one‑line drawings, study reports, device schedules and labeling packages.

Engineer & Build

With a signed‑off design in hand, fabrication begins in our UL‑listed Missouri panel shop. We custom‑build control panels, MCC buckets and prefabricated MCC buildings to UL 508A or UL 891 standards, ensuring disciplined QA and complete documentation. For projects requiring rapid deployment, we integrate MCCs, switchgear, HVAC, lighting and fire systems into prefabricated E‑House enclosures — see our Prefabricated E‑House service for examples. Before anything ships, we host witness FAT so your team can observe insulation resistance tests, relay functionality checks, labeling inspections and torque verification. This hands‑on review guarantees the system is ready for energization and AHJ approval.

Install & Commission

Once fabrication is complete, our field teams handle delivery, rigging and placement, ensuring panels and prefabricated buildings are anchored correctly. We perform all line/load terminations, point‑to‑point wiring checks, and verify mechanical and electrical interlocks, protective settings and labeling to meet NEC and ANSI requirements. During site acceptance and commissioning, we execute SAT protocols — insulation resistance tests, relay coordination checks, arc‑flash mitigation verification and protective device testing — for both low‑voltage UL 891 gear and medium‑voltage ANSI C37 systems. Finally, our technicians provide on‑site training, deliver as‑built documentation and maintenance schedules and hand over a complete turnover package. For more detail, see our Turnkey Switchgear Installation and Testing & Commissioning Services pages.

Modernize & Maintain

Power infrastructure doesn’t last forever, and retrofitting is often more practical than full replacement. We replace obsolete MCC buckets, starters, drives and circuit breakers with modern vacuum or air‑insulated types; upgrade aging busbars and conductors to higher‑rated copper and improved bracing; install digital relays that add arc‑flash mitigation, fault detection and SCADA‑ready communications; and integrate metering, PLCs and Ethernet/IP‑based communications for real‑time monitoring and remote control. Our team also coordinates switchgear with generator ATS, PLC panels and MCCs to ensure full‑system harmony. Documentation isn’t an afterthought — we update one‑lines, schematics and labels to reflect field conditions, prepare QA records for AHJ review, and migrate legacy panels to UL 508A builds, all while planning around outage windows to minimise downtime. For comprehensive modernization services, visit our Switchgear Modernization & Integration page.

Additional Services & Capabilities

- Testing & Commissioning – Our in‑house QA team performs FAT and SAT, validating insulation resistance, breaker functionality, arc‑flash protection, labeling and metering accuracy. See our Testing & Commissioning Services for more details.

- Turnkey Installation – We manage complete projects from one‑line review and system engineering through fabrication, rigging, grounding, labeling and final energization. Learn more on our Turnkey Switchgear Installation page.

- Prefabricated Buildings – We design and build fully integrated MCC rooms and switchgear E‑Houses delivered ready to hook up. Explore our Prefabricated E‑Houses to see available options.

- Remote Monitoring & Maintenance – SCADA integration, power metering and remote diagnostics keep your systems running efficiently.

- Preventive Maintenance Programs – Scheduled inspections, infrared scans, torque checks and relay calibration detect issues before they cause downtime.

Technical Excellence & Compliance

- We engineer and build to UL 508A (industrial control panels), UL 891 (switchboards), UL 1558 (metal‑clad switchgear) and ANSI C37 standards.

- Our engineers perform load flow, fault, coordination and arc‑flash studies and produce coordination curves, SCCR labels and study reports.

- Enclosures are designed for NEMA 1/3R/4X/12 indoor and outdoor ratings, with Class I Div 2 options for hazardous locations.

- QA protocols include FAT, SAT, torque tables, labeling packages and full documentation for AHJ and utility approval.

- We integrate PLCs, SCADA and HMIs using protocols such as EtherNet/IP and Modbus TCP, and provide remote monitoring and metering capabilities.

Our Process: From Consultation to Long‑Term Support

Consult & Design

Review your one‑line and process requirements; perform studies and draft preliminary designs.

Engineer & Build

Fabricate panels, MCCs and prefabricated buildings under strict QA, then host witness FAT.

Deliver & Install

Coordinate shipping, rigging and field terminations; prepare for energization.

Commission & Train

Perform SAT, verify protective settings, integrate controls and train operators.

Support & Maintain

Provide preventive maintenance, documentation updates and retrofit services throughout the life of your system.

Industries We Serve

Why Choose Pinnacle

Partnering with Pinnacle Power & Controls means you get more than a products supplier — you gain an engineering partner committed to your success:

- Engineer‑to‑Engineer Collaboration – Work directly with our engineers from concept to commissioning.

- Made in the USA & Global Delivery – Our panels, MCCs and prefabricated buildings are built in Missouri and delivered worldwide.

- Integrated, Full‑Lifecycle Services – We design, build, install, commission and modernize your systems under one roof, simplifying procurement and ensuring consistent quality.

- Compliance & QA Assurance – Every system is UL‑listed and shipped with complete documentation, testing records and labeling for AHJ and utility approval.

- Flexible Scheduling – We plan work around your outage windows and offer rush fabrication when time is critical.

- Long‑Term Support – Preventive maintenance, retrofits and remote monitoring keep your systems safe, reliable and future‑ready.

FAQs

Yes. We design and build panels, MCCs and switchgear in UL 508A, UL 891 and ANSI C37 certified facilities and provide documentation packages for inspection.

Absolutely. Our consult & design services include load flow, short‑circuit, coordination and arc‑flash studies to ensure safe and compliant designs.

Yes. We invite clients to witness or remotely observe FAT to verify wiring, labeling, relay settings and functional tests.

Yes. Our field teams manage delivery, rigging, cable terminations and site acceptance testing. We also commission protective settings and train operators.

Our modernization services replace obsolete breakers, busbars, relays and meters; update documentation; and convert legacy panels to UL 508A builds while planning around your outage windows.

Let’s Build Your Next Project Together

Whether you’re starting a new facility, upgrading legacy infrastructure or planning a major expansion, Pinnacle Power & Controls offers the full‑lifecycle project support you need. Ready to take the next step?

Send Your One‑Line or Talk to an Engineer and let us help you design, build, commission and maintain safe, reliable and compliant electrical systems.