Smart Logic. Real-Time Control. Built to UL 508A Standards.

At Pinnacle Power & Controls, we design and build UL 508A-certified PLC and SCADA control panels for industrial automation environments where uptime, safety, and precision matter. Our systems integrate Programmable Logic Controllers (PLCs) with Supervisory Control and Data Acquisition (SCADA) interfaces to give you full visibility, logic control, and real-time diagnostics across your operations.

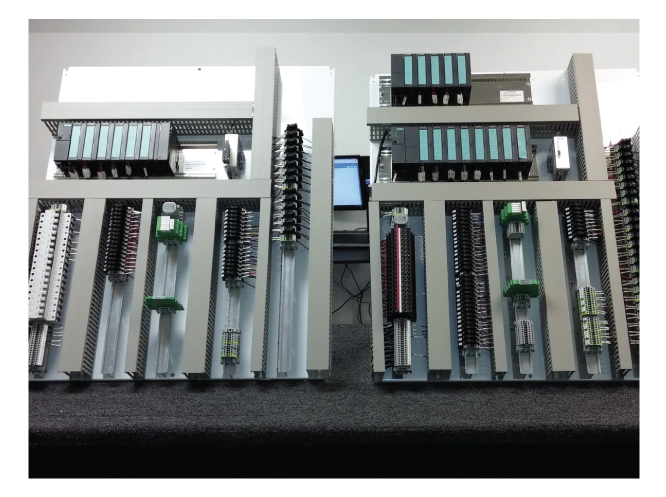

From standalone PLC enclosures to multi-bay SCADA cabinets with HMI displays and remote telemetry, we build automation panels tailored to your exact application, including I/O mapping, protocol compatibility (Modbus, Ethernet/IP, DNP3), and enclosure requirements (NEMA 1, 3R, 4X, Class I Div 2). Whether you’re managing batching in a food plant, remote well pads, or lift station automation, Pinnacle gives you intelligent control, engineered fast and field-ready.

What Are PLC & SCADA Control Panels?

The Brains Behind Industrial Automation

PLC and SCADA control panels are the core of smart industrial automation, combining programmable logic with remote visualization to streamline equipment control, reduce downtime, and enable scalable operations.

A PLC control panel contains a programmable logic controller configured to automate tasks like motor starts, batching, interlocks, alarms, and sequencing. These panels manage digital and analog I/O, and can support everything from relay replacement to full process logic. Our panels are engineered to accommodate all major PLC platforms, including Allen-Bradley, Siemens, GE, and Schneider.

SCADA panels go further, enabling real-time monitoring, data logging, remote alerts, and integration with HMI (Human-Machine Interface) displays. From single-station systems to multi-site SCADA networks, Pinnacle builds panels that help operators see, analyze, and act faster.

Every PLC & SCADA panel we build is UL 508A certified, and tailored to your specs — from enclosure rating (NEMA 4X, Class I Div 2) to communication protocols (Ethernet/IP, Modbus TCP, RS-485).

PLC + SCADA Features & Engineering Highlights

Smart Automation, Built In. Fully Integrated. Field Ready.

At Pinnacle Power & Controls, our PLC + SCADA panels are engineered for precision automation, combining robust logic processing with real-time data visibility and remote control. Every panel we build is designed to reduce manual intervention, increase equipment uptime, and simplify compliance.

Whether you’re running a multi-tank batching process, a packaging line, or an entire plant SCADA network, our systems scale with your operation. We support ladder logic, function block, and structured text programming, along with full I/O mapping, alarm routing, and touchscreen HMI integration.

Each panel includes provisions for:

- Modular PLC hardware (Allen-Bradley, Siemens, GE, etc.)

- SCADA software compatibility (Wonderware, Ignition, FactoryTalk)

- Built-in Ethernet, RS-232/485, Modbus, BACnet

- Data logging & historian support

- Remote access via VPN, 4G LTE, or fiber uplinks

Your build may also include smart sensors, signal converters, UPS backup, and condition monitoring devices, depending on your process. All systems are load-tested and delivered with complete documentation, including program backups, tagged wiring diagrams, and point-to-point test reports.

Whether you need a single enclosure or a distributed network of SCADA-ready panels, we make integration easy.

Panel Types We Build – Tailored PLC + SCADA Solutions

Purpose-Built Automation Panels. Ready for Real-World Processes.

At Pinnacle Power & Controls, we don’t build generic control panels — we build application-specific PLC + SCADA systems engineered to simplify your automation workflows. Whether you need a compact panel for remote I/O, a networked SCADA node, or a multi-enclosure logic system, our engineers tailor every build for the job site, voltage, I/O count, and control philosophy.

We support major PLC brands like Allen-Bradley, Siemens, and GE Fanuc, and design for full interoperability with upstream HMI/SCADA software, including Ignition, FactoryTalk, and Wonderware. Panels are pre-programmed or integration-ready and shipped with all wiring schedules, firmware backups, and IP/network assignments.

Common PLC + SCADA Panel Types We Engineer:

Industries We Serve with PLC & SCADA Panels

Smart Automation Panels, Built for Your Industry

PLC and SCADA control panels are only effective when they’re tailored to the realities of your environment. At Pinnacle Power & Controls, we build automation systems that match your industry’s regulatory codes, site conditions, and control needs — from water utilities and food processors to oilfields and factory lines.

Whether you need a Class I Div 2-rated PLC enclosure or a NEMA 4X SCADA head-end, every panel is built in our UL 508A-certified facility, load-tested, and shipped with field-ready documentation. Our team works directly with plant managers, OEMs, and engineers to design systems that drive uptime and real-time visibility.

Key Industry Applications:

Why Pinnacle for PLC + SCADA Control Systems

UL-Certified. Built Smarter. Backed by Engineering That Gets It.

At Pinnacle Power & Controls, we don’t just build control panels. We engineer automation systems that perform under pressure. Every PLC and SCADA control panel is fabricated in our UL 508A-certified U.S. facility, rigorously tested, and built with your compliance, safety, and integration needs in mind.

We collaborate directly with facility engineers, OEMs, and EPCs to design smarter systems — from pump logic and digital I/O to SCADA interfaces and remote diagnostics. Whether it’s Allen-Bradley, Siemens, Schneider, or ABB, we support the PLCs you use. Our builds are also ISO-aligned, documentation-rich, and ready for AHJ inspection.

With lead times as short as 2–4 weeks, and engineering support that extends through commissioning and beyond, Pinnacle helps facilities reduce downtime, avoid scope creep, and build with confidence.

Why Engineers & OEMs Choose Pinnacle:

UL 508A + NEC/NFPA Compliant

Fully certified panels, built to meet U.S. and municipal electrical codes.

Engineer-to-Engineer Collaboration

You speak directly with our in-house technical team — no middle layer.

2–4 Week Lead Times (Rush Available)

We deliver faster, with no compromise on testing or documentation.

Full PLC/SCADA Integration

Configured for your logic sequences, I/O count, protocols, and dashboards.

Documentation & QA Built-In

Certified schematics, load schedules, and factory QA — ready for inspection.

U.S. Manufacturing, Nationwide Reach

Built in Missouri. Delivered fast across the country.

FAQs – PLC + SCADA Panel Systems

Yes. Every PLC or SCADA panel we manufacture is built in our UL 508A-certified U.S. facility. Each unit includes certified testing, labeling, and documentation to meet NEC, NFPA, and local AHJ inspection requirements.

We typically need:

- Voltage and phase

- PLC brand preference (Allen-Bradley, Siemens, etc.)

- I/O count and type (digital/analog)

- HMI or SCADA integration needs

- Enclosure type (NEMA rating, indoor/outdoor)

- Control sequence or functional spec (if available)

Absolutely. We regularly build HMI/PLC/SCADA-integrated systems using touchscreens, remote I/O racks, and Modbus or Ethernet/IP-ready dashboards.

Standard lead times are 2–4 weeks,s depending on build complexity. Rush production is available for time-sensitive or shutdown-critical projects.

Yes. We offer:

- Remote support for troubleshooting and updates

- Retrofit services for legacy PLC/HMI systems

- Complete QA documentation and as-built schematics

Let’s Automate Smarter — Together

Ready to Build Your PLC + SCADA Control System?

Whether you’re engineering a new process line, upgrading a legacy control system, or integrating remote I/O into your facility, Pinnacle Power & Controls is your partner for smarter, faster industrial automation.

We design and manufacture UL 508A-certified PLC and SCADA panels with the intelligence, flexibility, and compliance your operation demands. From pump control to factory-wide automation, every system is engineered for integration, uptime, and long-term support.

📍 Made in Missouri. Trusted Nationwide.

📞 Need specs, pricing, or guidance? Talk to an automation expert today.